We’re leaving our thumbprint on the industry.

To reach the furthest and do the most good, we focus on three areas: people, partners, and the plant.

A place where people come first

Our real power is in our people and our shared commitment to giving back to the communities that we serve.

A family of brands

Because well-being is personal, we make brands and products to fit different preferences and lifestyles.

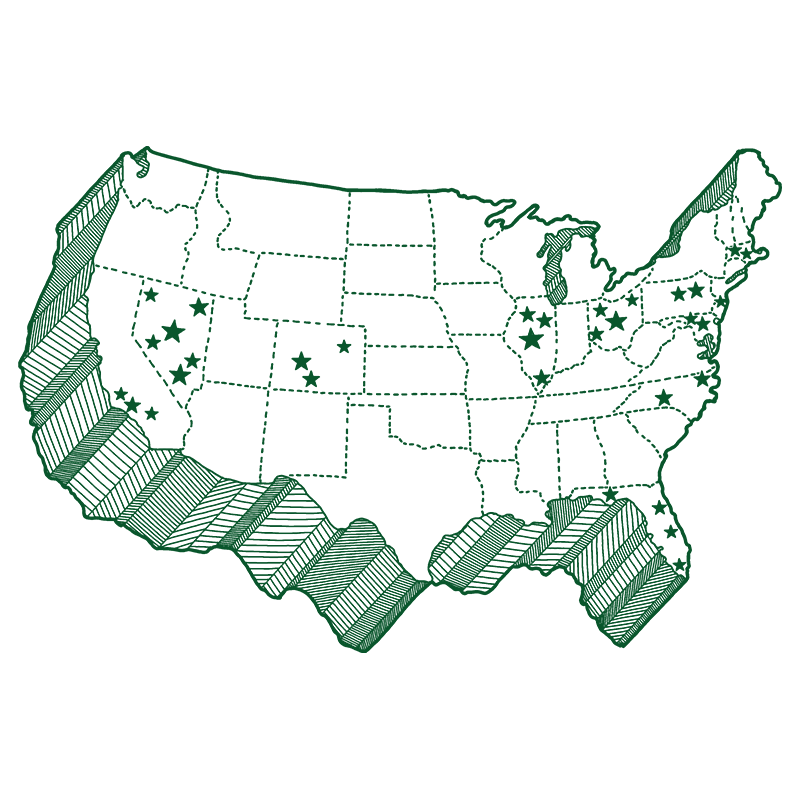

Award-winning national retail

Our retail stores prioritize educational and explorative experiences, shepherded by our People Care Specialists.

Forward—thinking investing

We’re building the future of cannabis today. Together our team is creating and capturing opportunities with future-minded branding and retail experiences.